Actuator is go! – ProWellTech

Today’s the big day! After months of toiling away in roundups, Actuator is finally graduating to your inbox as the latest addition to the ProWellTech newsletter family. I’ve written 40 of these things since our quiet, pre-name test launch back in February (we called ourselves “Robotics Roundup” for a few unfortunate months there). You can check out the full backlog here, and if you’re still reading this through ProWellTech.com, be sure to sign up here.

Seeing as how we’re nearing the end of another very weird year, I plan to spend the next couple of weeks exploring 2021’s biggest robotics trends. Think about it like Spotify Wrapped, only instead of an embarrassing number of Steely Dan songs (definitely not talking about myself here), we’ll take a look at the trends in automation, AI, research and investment that defined the last 12 months. And in doing so, we should get a better picture of the world we’re heading into.

I’ve been threatening to launch a robotics newsletter at TC for a number of years now — probably dating back nearly as far as our first big robotics event in Boston, way back in 2017. It’s been a rich vein for some time, but honestly, I don’t think we could have picked a better moment to launch this thing than right now.

As we stare down the two-year anniversary of a global pandemic, it’s clear that for many of us there may not be a “normal” to return to — for better or worse. For those in the robotics industry, this is the first glimpse into something big, bold and exciting. Maybe it’s overly optimistic to imply that we might emerge from this to something better (and believe me, the last 21 or so months have sucked deeply on a personal level), but it’s undeniably time to rethink the way we do just about everything. Logistics, healthcare, restaurants, agriculture, retail — all of these categories are set to be fundamentally transformed by COVID-19. And robotics has an important role in that transformation.

It’s been nearly two years, and countless industries are still under tremendous strain to fill positions. Those who have previously considered full automation a distant pipe dream are looking far more aggressively into these solutions, and as a result, we’ve seen a tremendous uptick in investments across a broad range of categories. Concepts that VCs would have traditionally balked at as too far afield have found their way to the tops of term sheets across the world.

I’ve been writing about technology professionally for a long time now, and for the first time, I’m hearing people talk seriously about robotic ubiquity in the present tense. Just before Thanksgiving, I spoke with Matthew Johnson-Roberson, who had just been appointed the head of Carnegie Mellon’s Robotics Institute. He told me:

We’re really at this inflection point when it comes to big, deployed robotic field systems out there in the world. One day, I want it to be that you look out your window, wherever you are in the U.S. and the world, and you see a robot doing something useful.

We’re not quite there yet, obviously. But I do fundamentally believe that we’re a lot closer to that goal than we were in, say, January 2020. Part of our job here going forward is discussing how we get there. We should also be taking the opportunity to discuss the consequences of getting there. What all of this means for things like jobs, quality of life and the environment, for example. And, not to put too fine a point on it, how to ensure that robotics continues to serve us and not the other way around.

Committing to an indefinitely weekly newsletter is something that felt a bit daunting at first blush. But having done it every week for a while now, one thing’s for certain: We won’t be running out of things to discuss any time soon.

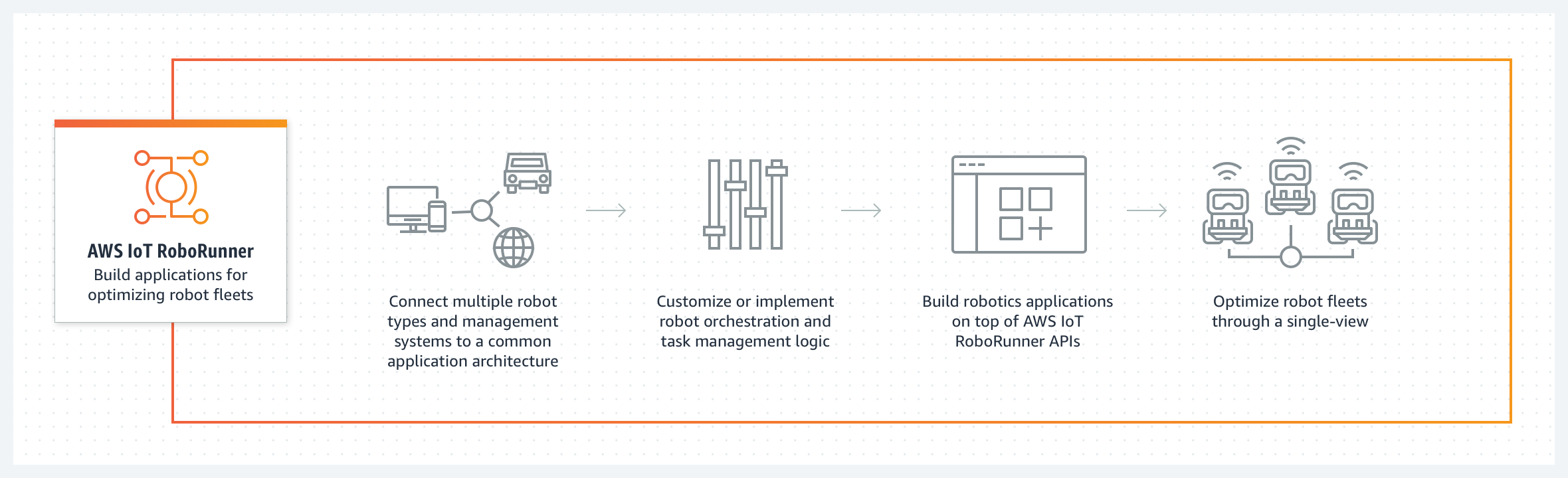

Image Credits: AWS

Heck, I may have taken the week off (happy belated Thanksgiving to those who celebrate), but robotics didn’t. My buddy Frederic is in beautiful Las Vegas, Nevada this week for AWS’s re:Invent conference. Amazon kicked off the show with the launch of a robotics fleet management program. The problem RoboRunner is attempting to solve is one we’ve seen various startups take on. Specifically, how do companies get different brands of robotics systems to play nicely together?

Here’s AWS CTO Werner Vogels:

Today, there are only a few successful commercial robotics companies, and there are a few big reasons for this. First, finding a fit in the robotics product market is difficult because real-world environments are dynamic and unpredictable, so pairing the right niche with the right capabilities can be a challenge. Second, building robots with a high degree of autonomy and intelligence requires multidisciplinary skills that are hard to find and recruit for. Third, robotics is capital intensive and requires large up-front investment in sensors, actuators, and mechanical hardware even when they’re already commercially available.

Can Amazon gobble up industrial robotics fleet management the way it has…well, everything else, basically? The company certainly has the infrastructure and resources to take the disjointed category on. It also now has a foot in the world of early-stage robotics startups, courtesy of a new partnership with MassRobotics. Amazon is teaming up with the Boston-based tech hub to launch a new robotics accelerator specifically focused on AWS applications.

Image Credits: Nuro

Autonomous delivery company Nuro just announced another massive raise. This latest $600 million round was led by Tiger Global Management (because, of course). It brings the company’s valuation to a whopping $8.6 billion. As for where that funding is going, co-founder Dave Ferguson told ProWellTech, “With the boost of this new funding, we’re turning our focus to commercializing and scaling the production of our third-generation vehicle at our new facility in Southern Nevada.”

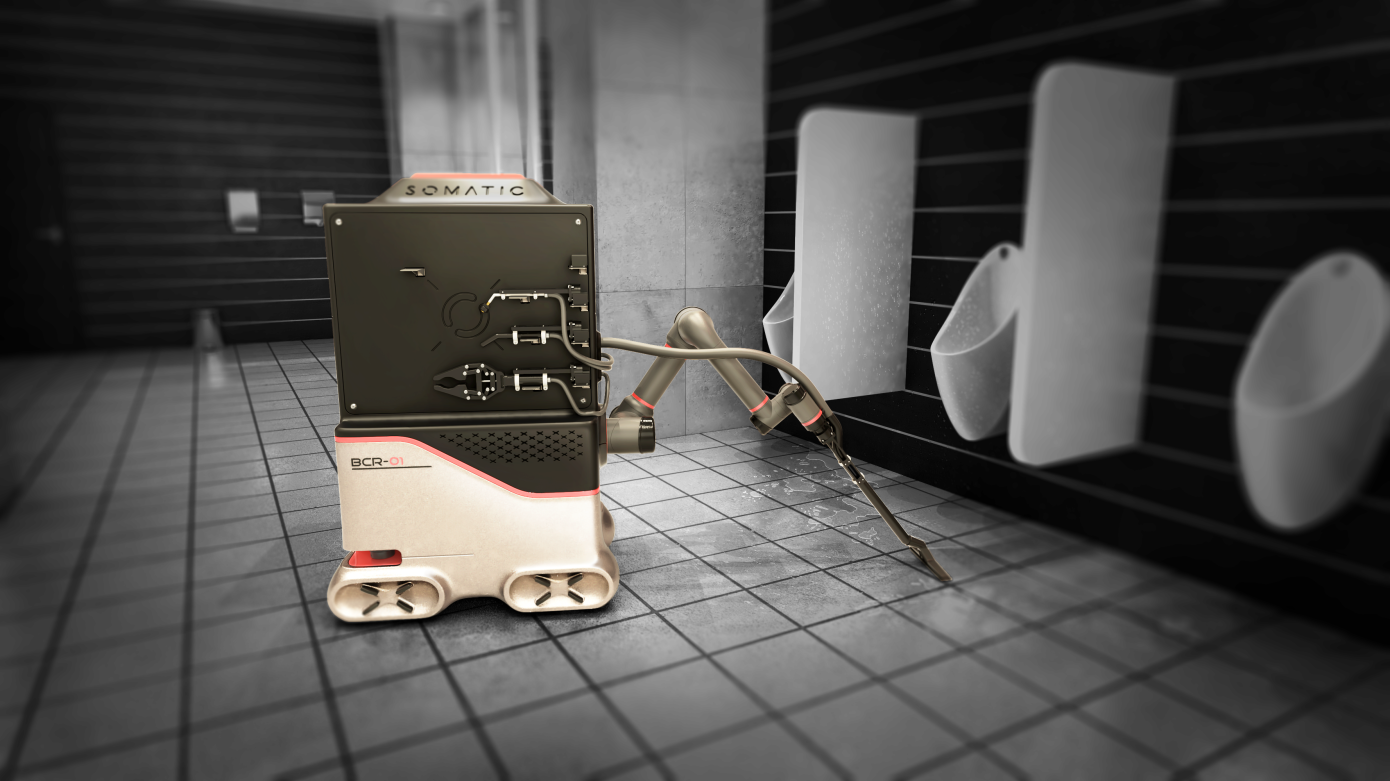

Image Credits: Somatic

When we talk about the dirty jobs that automation could one day replace, cleaning public toilets is no doubt near the top of the list. Michael Levy, the CEO of Somatic, dropped me a line to note that the company’s robot has reached a new milestone in automatous bathroom scrubbing, as evidenced by the below video:

The company, which effectively came out of stealth at our robotics event last year, has designed a system capable of riding in an elevator, opening doors and scrubbing down bathrooms.

As Levy told me last year, “The reason bathrooms are such a good application is because everything is bolted down to the floor. Things move in a predictable way. All commercial bathrooms built after 1994 are ADA compliant. What’s good for robotics is that lays a specific design.”

Image Credits: FJDynamics

Some more big funding for a robotics agtech firm — this time in China. Founded by former DJI chief scientist Wu Di, FJDynamics just announced that it has closed a $70 million Series B for its robotic harvester. Rita had a frank conversation with Wu, who noted, “You can have the most advanced AI algorithms. But if the technology doesn’t work on the production line or the farm, because you don’t have any industry experience, then how does your technology benefit people?”

Fair enough.

Image Credit: Miso Robotics

On the note of broader trends to look out for, anecdotally, it seems there’s raring to be an uptick in crowded capital rounds. Miso Robotics, which produces the hamburger cooking robot, Flippy, just announced a sizable $35 million crowdfunded Series B spread out over 8,200 investors (a list that includes both new and returning names).

It’s a big round, as far as crowdfunding goes — and a trend worth keeping an eye on. Certainly there’s something to be said for widescale consumer buy-in, but one wonders what going this route means for investor confidence, among other things.

Image Credits: Stellar

Earlier this week, Stellar Pizza announced plans to launch its robotic pizza cooking truck in Los Angeles at some point next spring. Formed by a trio of SpaceX expats, the company says its trucks are capable of cooking a pizza from scratch in less than five minutes and producing a pizza every 45 seconds at max capacity.

Per its press material:

With a revolutionary new pizza machine, Stellar Pizza transforms raw pizza dough and fresh toppings into a fully baked pizza in under five minutes. With the maximum capability to produce a pizza every 45 seconds, the food truck can deliver a larger quantity of fresh, gourmet pizzas more consistently than its brick-and-mortar counterparts. The robotic pizza-making process starts with a freshly prepared ball of raw pizza dough, which gets pressed and shaped into a round pizza crust. Then, house-made sauce and fresh toppings are added. Lastly, the raw pizza is inserted into one of four high-temperature custom-designed ovens to bake to perfection.

Hopefully the robotic pizza truck business proves a smoother ride for Stellar than it did for Zume, which has since undergone one of the weirdest pivots in recent memory and is now producing sustainable packaging with help from ABB.

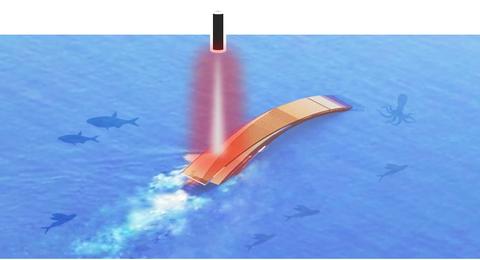

Image Credits: UC RiversideNeusbot comes to us from UC Riverside this week. The soft robot moves as iron oxide and copper nanorods convert light into heat. A team at the school believes the technology could be used to help clean oil spills in the future. “Normally, people send ships to the scene of an oil spill to clean by hand,” researcher Zhiwei Li says in a release tied to the news. “Neusbot could do this work like a robot vacuum, but on the water’s surface.”

Computer rendering of what the final Semiramis hanging garden structure will look like. Image Credits: Gramazio Kohler Research

A fun one from ETH Zurich to close us out. The school is using construction robots to blur the lines between architecture and art with the creation of an homage to the hanging gardens of Babylon — one of the Seven Wonders of the Ancient World. An aside from the piece by Devin that is simultaneously surprising and completely on-brand:

The project is a sort of huge sculptural planter, “hanging gardens” inspired by the legendary structures in the ancient city of Babylon. (Incidentally, it was my ancestor, Robert Koldewey, who excavated/looted the famous Ishtar Gate to the place.)

Learn something new about one of your co-workers every day.